PHARMACEUTICAL INDUSTRY;

MOBILE HEALTHCARE UNITS

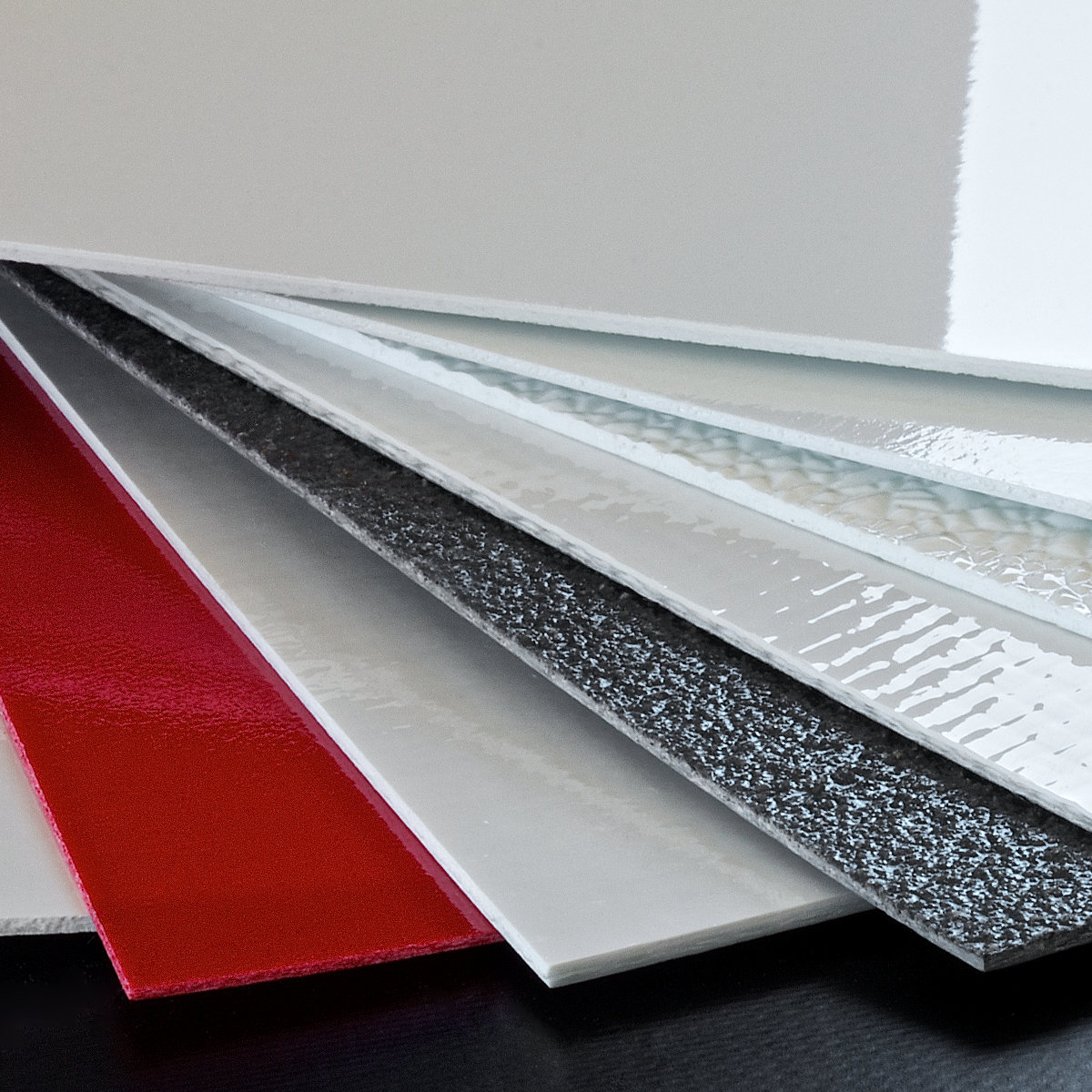

Antibacterial and Extra-Strong options of Decopan Medical glass fiber reinforced laminates provide private and university hospitals with extra hygiene and strength for maximum prevention with highest durability.

Ceiling and wall panels manufactured with Decopan Medical GRP sheets are the choice of global and domestic pharmaceutical companies’ facilities for top hygiene.

Wall and dropped ceiling panels covered with Decopan Medical GRP sheets are used widely in medical examination, diagnostic, treatment, production, manufacturing and warehousing units, where medical hygiene, or sterilization for antebacterial or antiviral prevention is needed.

108 options and more to come...

Decopan Medical GRP sheet product range, with broad application and advantages, is expanding according to R&D activities for healthcare industry and facilities.

The expansion with easy-to-sterilize options, have been kept persistent in order to fullfill the demands of research units, laboratories as well as vaccine production and warehousing facilities due to the advancements of medical standards and pandemic.

Panels covered with Decopan Medical hygienic glass fibre reinforced composite laminates provide constructors / contractors and facility management with faster construction and easier application of new or existing walls and dropped ceiling systems. This is a noteworthy advance when hospital expansion is needed from intensive care units and patient rooms to all units of the facility.

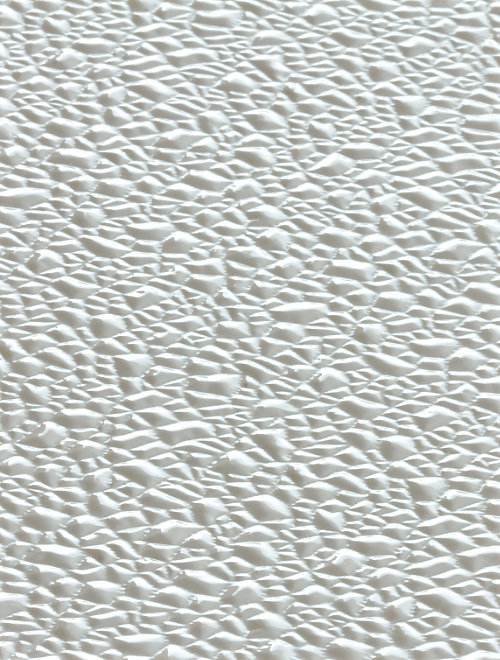

New Antibacterial

Wall and ceiling panels, built with new Antibacterial GRP sheets are used in operating, emergency and delivery rooms; intensive care units, laboratories . Medical laminates provide antiviral protection with easily disinfectable material characteristics.

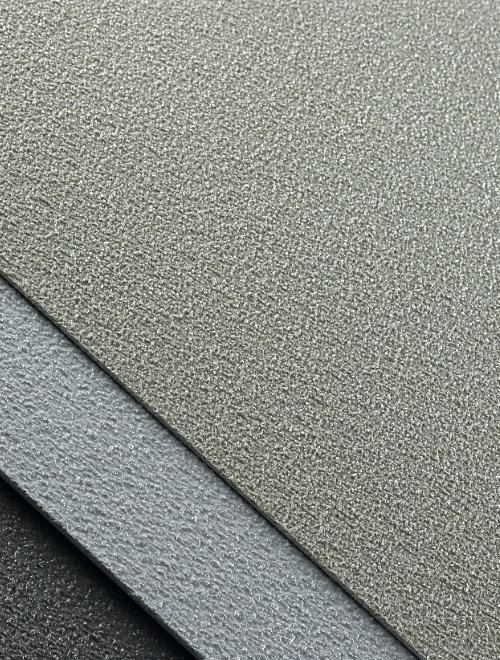

New Epoxy Extra-Strong

Epoxy Extra-Strong Decopan Glass fiber Reinforced products are lighter but stronger. Epoxy resin matrix increases the mechanical properties of the composite and make the material stronger comparing to standard polyester laminates. Extra-Strong laminates, available in Quadraxial, Biaxial and standard woven rowing are ideal for mobile healthcare and medical warehousing where extra-resistance is needed.

Strength and safety

Decopan Medical Fibre Reinforced Plastic laminates are regularly tested at internationally accredited laboratories.

Global pharmaceutical companies, internationally accredited specialty medical centers and Turkish university hospitals are among the top in our customer references inventory regarding medical hygiene, safety and strength.

- Resistance

Heat resistant from - 40 °C to + 120 °C.

Moisture resistant. Waterproof.

Resistant to UV and surface aging.

Resistant to chemicals.

Anti-corrosive.

Resistant to impacts and crashes.

- Medical Safety

Antibacterial Decopan Medical laminates are tested according to JIS Z 2801:2012.

Various accredited microorganism growth tests confirmed that no bacteria regrowth was observed after disinfection.

- Fire Safety

Some test results of Decopan products with our optional Fire Safety special formula alternatives are as follows:

Tested in accordance with BS 476 Part 7 standard and classified as Class 1.

Anti-Slip laminates used in ambulances. clinic entrance ramps etc. have been tested in accordance with NF F 16-101 standard and classified as M1/F1.

Tested according to DIN 4102 and classified as Class B2 Fire Resistant.

- Electrical Safety

Decopan Medical FRP / GRP laminates are electrically non-conductive and avoid high voltage arc discharges.

- Hygienic Safety

Decopan FRP / GRP laminates prevent bacterial, fungal and mold growth in sanitary areas as bathrooms or shower cabinets.

Easily disinfected with all types of surface disinfectants.

Technical specs for Anti-Bacterial and Extra Strong GRP / FRP laminates vary based on product selected.

Fire Safety is optional.

All product, product specifications and data are subject to change without notice to improve reliability, performance, function, design or otherwise. Contact our Sales Team for latest specs and other data.

Decopan Medical FRP / GRP sheet samples are tested at trusted internationally accredited laboratories.

Decopan Medical

laminates have limitless variants under 8 main categories.

↔ max 3200 mm

↕ 1.40 - 3.00 mm

⇄ 60 m

Uniform thickness

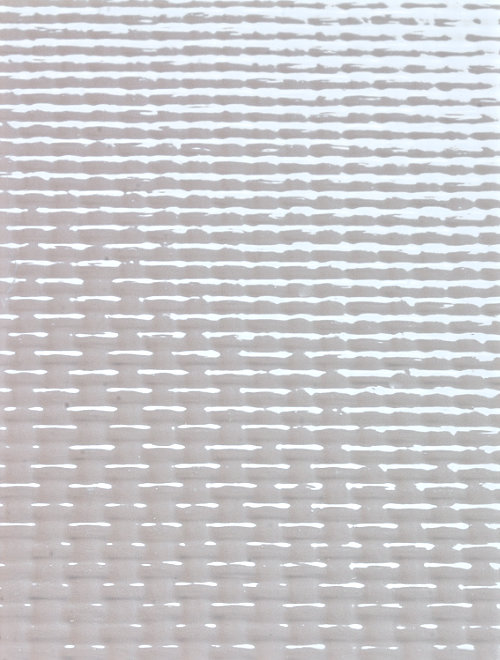

Film grooved, smooth, open fibers bonding side options

↔ max 3200 mm

↕ 0.80 - 1.60 mm

High resistance

High elasticity

Glossy or matt finish

Extra UV resistance and weathering protection

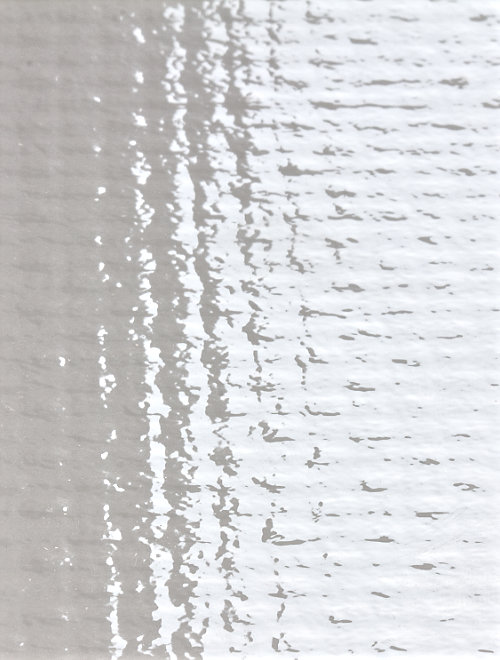

Smooth, sanded (rough) or corona-treated bonding side

↔ max 3200 mm

↕ 1.30 - 5.00 mm

High tensile and mechanical strength

Glossy or matt finish

Smooth, sanded (rough) or corona-treated bonding side

↔ max 3200 mm

↕ 1.40 - 3.00 mm

⇄ 60 m

Uniform thickness

Film grooved, smooth, open fibers bonding side options

↔ max 2950 mm

↕ 1.20 - 5.00 mm

Best for easy-to-clean interiors

Smooth, sanded (rough) or corona-treated bonding side

↔ max 3200 mm

↕ 1.00 - 5.00 mm

Budget solution for interiors and underfloor use

Self-coloured structure

Low Thermal Expansion Coefficient

Smooth, sanded (rough) or corona-treated bonding side

↔ max 3200 mm

↕ 1.15 - 5.00 mm

Low Thermal Expansion Coefficient

Glossy or matt finish

High UV resistance

Smooth, sanded (rough) or corona-treated bonding side

Fire resistance with M1/F1 rating

↔ max 2800 mm

↕ 2.00 - 2.30 mm

Dimensions suitable for monolithic flooring

Ready-to-use laminates

Smooth, sanded (rough) or corona-treated bonding side

Across our customer references...

Decopan Medical products are used in internationally accredited health centers, university hospitals, and global pharmaceutical companies’ production facilities.

Surgery Rooms / Operating Theaters

Decopan Medical GRP sheets support hygiene in the second brain hospital in Europe as well as university and private hospitals.

Clinics / Units

Decopan Medical products keep patients, health professionals and public safe, in either major university hospitals or small practices / clinics.

Healthcare Industry

Established pharmaceutical companies keep their process lines safe in facilities covered with Decopan Medical GRP laminates.